#332698 - 04/05/2010 00:07

Engineering/Mechanics lever questions/calculations.

Engineering/Mechanics lever questions/calculations.

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

This is in relation to something I mentioned in another thread, specifically about a storage ottoman I've designed and built. It's a large piece and in addition to hinges it must feature gas springs to help the user lift the top as well as keep it open. At the moment I'm trying to figure out which gas lifts/springs to buy and have a choice of a number of parts each with a rated force/lift capacity. Since the lifts will attach closer to the pivot or fulcrum point of the lid, I expect there to be a mechanical disadvantage, which I'd like to calculate. And seeing as I don't envision a career in applied mechanics, nor have I really any background in it, I'm hoping someone can help me through this if I provide a few numbers and measurements. With a quick peek at wikipedia, I believe a hinged top is most similar to a class 3 lever, one which the force applied sits between the pivot and the load. Although in this specific case the load is really the weight of the entire lever (lid) itself, not at additional object at the end (front) of the lever. Here's an image of the ottoman frame with measurements. The most important one (from that image) is the distance from the pivot to the front of the top, which is 31" (the width of the ottoman frame).  The top weighs 26 lbs currently - that's without foam and upholstery. Maybe we can run two sets of calculations and make the second set with the weight at 30lbs Now I suppose the missing piece of information is the force point. That's currently to be decided and it has to be derived from the lengths of the gas lifts available and the desired angle of the lid at its most open position. I'm going to make a few sketches in the morning to show how this fits together and to try and decide on the force point. I've also got a photo of a commercial ottoman (smaller) with similar gas lifts in place. I may have to try a few different variations which will determine if the lift is applying any usable force in the closed position or not (greater assistance when opening from the closed position). Here's a PDF from a manufacturer of gas springs showing some calculations: http://www.acecontrols.com/PDF/Gas%20Spring%20Catalog-Revised%2005-2009.pdf

Edited by hybrid8 (04/05/2010 00:51)

|

|

Top

|

|

|

|

#332700 - 04/05/2010 01:00

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 25/12/2000

Posts: 16706

Loc: Raleigh, NC US

|

Well, the general equation is:

E = L * l / e

where:

E = exerted force

L = load force

l = distance of load from fulcrum

e = distance of exertion force from fulcrum

I see no reason you can't assume that the weight of the lid is at its center of gravity. Let's assume that's at the center.

So far we have:

E = 30 lbs * 15.5" / e

Since you haven't yet provided specs for your springs, let's say:

E * e = 465 inch-pounds = 38.75 ft-lbs

(Note that we're talking torque.)

That all assumes that all of the forces are being applied perpendicular to the lever arm, which is not true. How you mount the arm is significant, and you probably want to mount it so that it applies the most perpendicular force when the lid is open, so that it won't pop the lid open on its own. And, obviously, the direction of gravity changes in relation to the plane of the lid as it opens.

I guess what you want is to find the normal force exerted on the lid by gravity when open and when closed and then find a spring that has a rating between the two.

I don't know how the springs are spec'd, though.

_________________________

Bitt Faulk

|

|

Top

|

|

|

|

#332711 - 04/05/2010 02:20

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

|

old hand

Registered: 15/02/2002

Posts: 1049

|

Well, the general equation is:

E = L * l / e

where:

E = exerted force

L = load force

l = distance of load from fulcrum

e = distance of exertion force from fulcrum

I see no reason you can't assume that the weight of the lid is at its center of gravity. Let's assume that's at the center.

So far we have:

E = 30 lbs * 15.5" / e

Since you haven't yet provided specs for your springs, let's say:

E * e = 465 inch-pounds = 38.75 ft-lbs

(Note that we're talking torque.)

That all assumes that all of the forces are being applied perpendicular to the lever arm, which is not true. How you mount the arm is significant, and you probably want to mount it so that it applies the most perpendicular force when the lid is open, so that it won't pop the lid open on its own. And, obviously, the direction of gravity changes in relation to the plane of the lid as it opens.

I guess what you want is to find the normal force exerted on the lid by gravity when open and when closed and then find a spring that has a rating between the two.

I don't know how the springs are spec'd, though. The fact that the amount of torque changes as a function of the angle the lid is opened is the whole thing, unfortunately. At 90 degrees (opened vertically), there is no closing torque, at 0 degrees (closed) there is maximum torque. Torque = r (radius) x F (force). If you want the lid to stay in a certain position, you want the closing torque (from weight) to equal the opening torque (from the spring). If the spring is installed such that the force axis is parallel to the lid when closed, there will be no opening torque when the lid is closed (this is desirable). The action of the spring will increase as the angle opens, and when it matches the torque from the weight, the system will be in equilibrium. The trick to designing this is to not merely size the spring, but to pick the installation location such that the closing force and opening force are equal in the position you want the lid to remain when opened. The closing torque is equal to the weight of the lid times the lever arm over which it acts (always perpendicular to gravity). So what we need to know is the horizontal location of the center of gravity (CG) of the lid as a function of the opening angle. This is simply (length of the lid) / 2 * cos(theta), where theta is the opening angle. At 90 degrees, that equals zero, and at 0 degrees that equals half the lid length, which is where the CG is. Multiply this lever arm by the weight of the lid and you have the closing torque as a function of lid angle. The spring torque is more complex. You need to figure out the length of a perpendicular from the spring axis to the lid hinge. This is labled Lg on page 4 of the catalog you linked. Lg is the lever arm on which the spring acts, so the spring torque is equal to the spring force times this distance. This distance changes with opening angle. If you make yourself some drawings of the little spring and the triangle made by the spring and the base and the lid, and you draw the length Lg (perpendicular to the axis of the spring), with some patience and basic trigonometry, you can work out that length and multiply it by the spring force. Now that you have these two formulas (closing torque as a function of opening angle, and spring torque as a function of opening angle) you pick your desired static point (the angle at which you want it to hold itself) and set the two equations equal to each other and solve for the spring force you need. You also need to make sure that the spring has enough "throw" to handle the increase (or decrease) in length as the lid opens. A final complication is that the spring force will vary with length, but possibly not significantly enough to be considered here. I realize this little course in Statics is probably more than you were looking for. If I get some time tomorrow I'll work it out for you on paper -- this is difficult to describe in words and very simple to draw with some vector calculus and a diagram :-) Jim Edit: the spring force may also include a preload. Post a link to the springs you plan to use, as well as force vs. length profiles they have for them. Edit 2: I guess you did post a link to the spec sheet. On first glance, it doesn't seem to give what we really need to know, which is force as a function of stroke. It also occurs to me that you can make this whole geometry problem a lot easier by not solving for these forces as a function of angle. Just pick the angle you want as the stop point (like 75 degrees or something), and draw yourself a diagram. Figure out all the angles from there, and solve for the force required at that angle to counteract the torque from the weight of the lid. Don't forget to halve the spring force if you use 2 springs! Also remember that the closer you mount the spring to the hinge, the less stroke you will have, but the more force you will need. If you use a very short spring, then the mounting hardware you use will potentially need to handle quite a large force (up to hundreds of pounds, since the lever arm of the spring is so much shorter than the lever arm of the lid). Edit 3: Finally, a word about how these systems are designed in practice. Gas springs in particular lose their strength over time, so a common solution is to design a stop in the hinge mechanism and then use a larger-than-required spring. This will push the lid up against the stop and add to the closing force, but that's not that big of a deal. Remember that as the spring becomes co-linear with the horizontal lid, the opening force will drop to zero. In practice this is the best bet. You can just estimate the lever arm of the spring and compare it to half the width of the lid. Let's say the lever arm is 6" and half the width is 18", then the spring force needed is 3x the lid weight. So you pick a spring 4x the lid weight and design a stop into the hinge mechanism. I hope all this helps. Jim

Edited by TigerJimmy (04/05/2010 03:34)

|

|

Top

|

|

|

|

#332714 - 04/05/2010 11:44

Re: Engineering/Mechanics lever questions/calculations.

[Re: larry818]

Re: Engineering/Mechanics lever questions/calculations.

[Re: larry818]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

So I've come to a firm conclusion, which I had hypothesized last night. I will most definitely need help with this.  I haven't done any trig since high school, and definitely never any physics or statics. The spec sheet I linked to is just something I found on the net, not the springs I was specifically looking at. The springs I was thinking about were this brand: http://www.amazon.com/Attwood-SL34205-Sp...6462&sr=1-1They're available in a few configurations of force and length. I do plan to use two of them, on on each end of the lid, so we can cut the calculations in half. That link to McMaster-Carr is excellent, both in terms of calculations as well as component selection. For some reason I had a really hard time finding retail availability of an assortment of gas springs using Google. I probably should have hit that site directly and used their search. There are a number of considerations with the mounting orientation of the spring that I'll cover in my next post. I need to run a few errands, including taking my daughter for a walk this AM, so I'm out of time at the moment. Thanks for the very detailed explanations by the way!

|

|

Top

|

|

|

|

#332741 - 04/05/2010 20:48

Re: Engineering/Mechanics lever questions/calculations.

[Re: larry818]

Re: Engineering/Mechanics lever questions/calculations.

[Re: larry818]

|

old hand

Registered: 15/02/2002

Posts: 1049

|

Sure, that little table of horizontal to vertical lift solves the equations for the given geometry. Lots of engineering amounts to looking shit up on tables :-). Of course, if your geometry is significantly different, then the table won't work.

|

|

Top

|

|

|

|

#332742 - 04/05/2010 21:14

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

old hand

Registered: 15/02/2002

Posts: 1049

|

I'm not a fan of gas springs. Are you married to this design? There are other options, such as these that are a potentially more elegant solution. The hinge has a spring-loaded stop at 75 degrees.

|

|

Top

|

|

|

|

#332743 - 04/05/2010 21:53

Re: Engineering/Mechanics lever questions/calculations.

[Re: TigerJimmy]

Re: Engineering/Mechanics lever questions/calculations.

[Re: TigerJimmy]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

Those springs would be excellent for this type of application, and I especially like the soft-close aspect. However, the issues I have with those spring hinges are:

• Will work for box material up to 1" thick with flat lids (lids without sides)

• The manufacturer does not provide a weight rating for this product

The top on my box has sides. Small, but sides nonetheless. This would require building out an extension (anchor block) on the top to attach these. With no weight rating I'd have to build then try. Not a good option. I'm also really doubtful they'd be able to handle the weight of my ottoman top unfortunately. I believe the foam and upholstery may add up to another 24lbs to the weight of the top. I just weighted one of the leather covered pillows for my sectional and it's 12.2lbs, so I'm doubling it to be conservative. I'm still working on the illustration to show the top open and will put together some samples of positions for the gas springs. I'm totally open as to how they'll be mounted at this point. I'll also post up a photo I took of a commercial product.

Edited by hybrid8 (04/05/2010 21:55)

|

|

Top

|

|

|

|

#332840 - 10/05/2010 05:59

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

enthusiast

Registered: 06/08/2002

Posts: 333

Loc: The Pilbara, Western Australia

|

You could use linear actuators with limit switches and a remote control to open and close the lid, although then you would be tied to a power source. It would be pretty cool to just push a button and watch the lid open though! Edit: The TV lift on the above site may have been another solution to your motorised cover thread.

_________________________

Peter.

"I spent 90% of my money on women, drink and fast cars. The rest I wasted." - George Best

|

|

Top

|

|

|

|

#332891 - 11/05/2010 22:53

Re: Engineering/Mechanics lever questions/calculations.

[Re: pedrohoon]

Re: Engineering/Mechanics lever questions/calculations.

[Re: pedrohoon]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

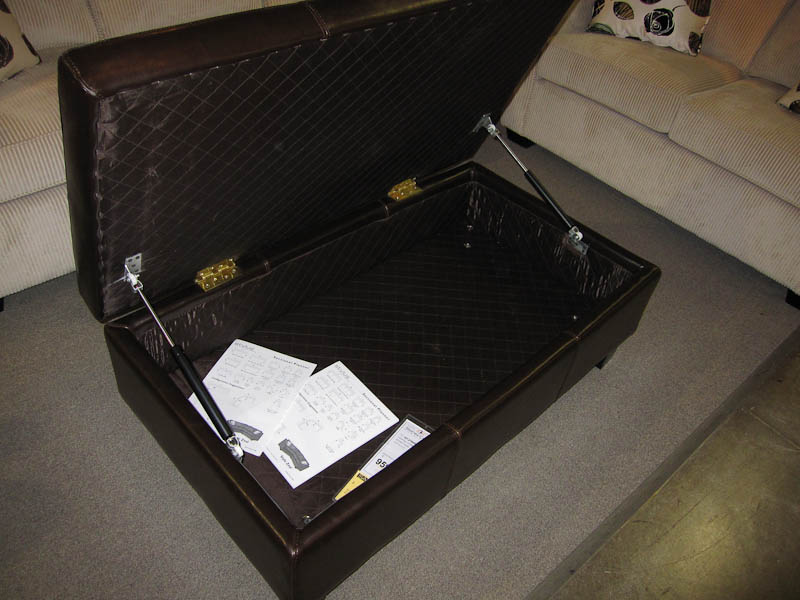

Ok, let's get back into it.  Sorry, but I've been a bit busy with my other construction projects and didn't get the images off my camera. The diagrams on the McMaster Carr site seem to orient the lift in the most sensible orientation. As you can see below, in this commercial Ottoman, not only did the install orient the lifts upside down (chamber down, piston up), but the install is also "rough" looking. The lifts are installed in a sort of backwards configuration compared to the illustrations and definitely don't aid at all in the first few inches when opening the top. This also means the top can slam shut in the last few inches. Maybe even a full foot. Not too good when concerned about little fingers. Incidentally, my ottoman should look a *lot* better than this unit when it's been upholstered and fitted with hardware.

Edited by hybrid8 (11/05/2010 22:55)

|

|

Top

|

|

|

|

#332904 - 12/05/2010 16:04

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 08/07/1999

Posts: 5561

Loc: Ajijic, Mexico

|

I'd like the top to open to 65 degrees which I've shown in the model below This is probably a dumb idea, and certainly not as elegant as what you intend... but as far as figuring out where the lift attachment points should be, could you make multiple pivot points like in the attached drawing and just use the ones that work best? tanstaafl.

_________________________

"There Ain't No Such Thing As A Free Lunch"

|

|

Top

|

|

|

|

#332906 - 12/05/2010 16:32

Re: Engineering/Mechanics lever questions/calculations.

[Re: tanstaafl.]

Re: Engineering/Mechanics lever questions/calculations.

[Re: tanstaafl.]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

I could make the multiple attachment points. But I still need to figure out one thing ahead of time.... Which lifts to buy.  In choosing those I need the right combination of compressed and extended length and force.

|

|

Top

|

|

|

|

#332908 - 12/05/2010 17:25

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 25/12/2000

Posts: 16706

Loc: Raleigh, NC US

|

Now you're into trigonometry.

Basically, you have two triangles. Let's call them ABC and ABC' where A is the point described by the hinge, B is the point where the spring attaches to the box, C is the point where the spring attaches to the lid when it's open, and C' is the point where the spring attaches to the lid when it's closed. There's also a line AA' that is parallel to the ground and (obviously) passes through A.

Data points you can define are the angles CAA' and C'AA', and the ratio between the lengths AC and AC' (probably 1:1, though it seems like there might be some possibilities for it to be different).

Limitations are the maximum and minimum lengths of BC and BC'.

I've attached a GeoGebra doc that should let you play around with it. The blue point below the x-axis is free. You can move it around and see what effect it has on the angles and distances. (The point names in the doc are not the same as the point names I described above.)

Attachments

BrunosHinge.ggb (395 downloads)

_________________________

Bitt Faulk

|

|

Top

|

|

|

|

#332909 - 12/05/2010 17:26

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 08/07/1999

Posts: 5561

Loc: Ajijic, Mexico

|

In choosing those I need the right combination of compressed and extended length and force. Ah, but that's the beauty of the different attachment points. By choosing different ones you can accommodate a variety of different lifts in terms of both extension and force. If your lift is anywhere close to what you need you can find a setup that works. tanstaafl.

_________________________

"There Ain't No Such Thing As A Free Lunch"

|

|

Top

|

|

|

|

#332913 - 12/05/2010 19:43

Re: Engineering/Mechanics lever questions/calculations.

[Re: tanstaafl.]

Re: Engineering/Mechanics lever questions/calculations.

[Re: tanstaafl.]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

Thanks for the doc Bitt, but it's not really helping me figure this out.  I don't see a point C' in the calculations. Also, while the distance of C to B' (the length of the spring) should change, their distances relative to A should not. Not when in operation anyway. Point B' also can't be at the very end of the line defined currently by AB' - it would take far too long a spring and it would get (more) in the way of the open sides.

|

|

Top

|

|

|

|

#332916 - 12/05/2010 21:04

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 25/12/2000

Posts: 16706

Loc: Raleigh, NC US

|

Okay, I've updated it with some new features, and rectified the labelling.

First, I added the possibility of an offset for where the spring attaches to the lid, which probably more closely matches reality. There's a slider that allows you to adjust that.

Second, I added a slider to control the fully-open angle, in case something other than 65° makes more sense.

Now, my point for this is to allow you to move point B (where the spring attaches inside the box) around to see the ratio of the lengths of the spring when open and closed, which I've also added as a text callout, as well as offset distances of B from the axes.

What this does not do is deal with the amount of force required. This is just to help determine placement.

Also note that I'm not depicting the entire lid, only the portion that the spring directly interacts with.

Attachments

BrunosHinge.ggb (332 downloads)

_________________________

Bitt Faulk

|

|

Top

|

|

|

|

#332920 - 12/05/2010 23:11

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

Also note that I'm not depicting the entire lid, only the portion that the spring directly interacts with. Ah! That makes a lot more sense then. I'll take a look tomorrow and hopefully it'll all make more sense to me. Thanks again.

|

|

Top

|

|

|

|

#333202 - 21/05/2010 18:10

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

I've narrowed down the range of lengths that should work and using the samples on the McMaster site as a guide decided on 60lbs of force per spring. I ended up with springs featuring

20.12" EXTENDED LENGTH, 8.27" STROKE = 11.85" collapsed

Those numbers include the ball joints, whereas the numbers on the linked page originally posted don't. Bitt, do you think you might modify the ggb file again to include a spring that can grow/shrink only between 11.85" and 20.12" along with a "lid" line whose hinge is fixed, but and point can be moved between 0 and 65 degrees (or more I suppose, but it'd be nice if there was some marker otherwise at 65). I don't know what's possible in that software, but it would be nice to be able to move and anchor both ends of the spring so that when the end point of the lid is moved about its arc, the spring line would shrink/grow. That would probably let me pic a few spots to try mounting these things. The most important part being demonstrated by the software being at what positions the spring will be able to allow the lid to open and close properly.

|

|

Top

|

|

|

|

#333233 - 22/05/2010 13:25

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 25/12/2000

Posts: 16706

Loc: Raleigh, NC US

|

This is about as close as I can come.

I added sliders to set the spring's extended length and stroke, and used those to calculate real-world dimensions.

I also added sliders for lid weight and spring force. In both cases, it's applied force, which isn't really linear, but, eh. I also added a movable point and vectors attached to it to indicate when the spring would be applying enough force to overcome the weight. Again, the forces are very oversimplified.

Remaining problems:

The lid mountpoint offset is still measured as a fraction of the unit circle, because trying to do it in inches creates a circular definition, and, honestly, I don't feel like redoing it that much. So a little fiddling will be required.

Also, since the scale of the diagram changes as you move the mount points and angles, you'll have to perform a manual feedback loop to get things nailed down.

Attachments

BrunosHinge.ggb (332 downloads)

_________________________

Bitt Faulk

|

|

Top

|

|

|

|

#333234 - 22/05/2010 14:56

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

I think I'm too stupid to figure out the latest changes to the file... I've just downloaded a physics tool pack for Sketchup which would be ideal because I'd theoretically be able to actuate the model I've already made, but so far, after 5 minutes of poking around, I haven't had any luck with the new tools.

EDIT... So I spent another 10 minutes and decided SketchyPhysics is a non-starter. It doesn't work for Mac OS. I've only found threads confirming this.

Edited by hybrid8 (22/05/2010 15:19)

|

|

Top

|

|

|

|

#333235 - 22/05/2010 16:03

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 25/12/2000

Posts: 16706

Loc: Raleigh, NC US

|

?

There are slider variables for the spring's length and stroke, the angle of the lid fully opened, the weight of the lid and the force of the spring, and how far the lid mount point needs to be recessed into the lid.

Then there is the point for the box mount point, which can be moved all around. When it's moved to a point where the spring will not fit, the lines describing the open and closed positions of the spring turn red.

There's also another movable point the shows the forces applied to the lid by gravity and the spring, with a callout showing distance above the box. When gravity overcomes the spring, the gravity vector turns red. When the spring overcomes gravity, its vector turns green.

The angles and lengths should all be accurate, the forces less so.

Edited by wfaulk (22/05/2010 16:04)

_________________________

Bitt Faulk

|

|

Top

|

|

|

|

#333237 - 22/05/2010 16:45

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

I understand what the sliders do as you've explained, but I don't know how to use what you've implemented to do what I think I need to do.

I know the spring parameters, so I don't want to manipulate them manually, but I'd like to set them as limits for the line representing the spring. I don't need to change them once they're set. I understand I can just leave the sliders where they are for this.

The way I imagine working the puzzle is to move (rotate) the lid about its hinge with the spring ends fixed to points I've set. So I thought I'd like to move both ends of the spring.

This is something that shouldn't have been that difficult to do in Sketchup so that's why I was trying that Physics plugin. However, I may have to give it a shot in a Windows VM. At this point I'm not so concerned about the forces because I don't even know where I can mount the ends of the spring to allow the lid to close (and open) properly (at all).

Edited by hybrid8 (22/05/2010 16:46)

|

|

Top

|

|

|

|

#333240 - 22/05/2010 18:05

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

It turns out that Sketchup for Windows and Mac OS both crash quite easily. I did finally get a basic hinge to work, but I haven't been able to set the properties on anything to allow me to manually open/close the box top. I've only ever been able to toss the whole assembly into the air to see the hinge working.

|

|

Top

|

|

|

|

#333248 - 22/05/2010 23:34

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 25/12/2000

Posts: 16706

Loc: Raleigh, NC US

|

The way I imagine working the puzzle is to move (rotate) the lid about its hinge with the spring ends fixed to points I've set. Okay, then set the endpoints and move the angle slider. You don't really need to look at all the intermediate points in the opening and closing, though; it's not going to do anything but compress as you close the lid. Said another way, the fully open position will always be when the spring is at full extension, and the closed position will have the spring as compressed as it's ever going to be, once installed.

_________________________

Bitt Faulk

|

|

Top

|

|

|

|

#333257 - 23/05/2010 10:50

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

I'll have to look at it again.... I don't recall being able to move the top endpoint of the spring, nor the end point of the lid though.

|

|

Top

|

|

|

|

#333260 - 23/05/2010 15:25

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 25/12/2000

Posts: 16706

Loc: Raleigh, NC US

|

The lid end point of the spring is always at the maximum throw of the spring. Everything else scales to that. There is a variable as to how far inside the lid the spring is mounted.

The end point of the lid isn't even depicted. It's not relevant. If you're talking about opening and closing, again, move the angle slider. But it's still only relevant if you want to change the fully-open angle. The compression of the spring is going to be reasonably linear through the opening/closing motion.

_________________________

Bitt Faulk

|

|

Top

|

|

|

|

#333265 - 23/05/2010 20:55

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

I do want to change the angle of the lid because the spring will only allow the lid to close for certain mounting positions. The maximum extension of the spring is what will end up defining the open angle, which I'm shooting to be about 65 degrees.

So what I wanted to do was manipulate the lid line through its arc while having the spring line shrink/grow by itself.

|

|

Top

|

|

|

|

#333266 - 24/05/2010 00:40

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

Re: Engineering/Mechanics lever questions/calculations.

[Re: hybrid8]

|

carpal tunnel

Registered: 25/12/2000

Posts: 16706

Loc: Raleigh, NC US

|

Why? What information are you going to gain by looking at the lid halfway closed? The fully extended length is when the lid is fully open. The most compressed length is when the lid is closed. Both of those are depicted in my diagram. The points in between are irrelevant; at no point will the spring need to be anything other than between those two extremes.

If you move the mounting positions somewhere where the spring would bottom out, the lines depicting the spring turn red.

Set your desired fully-open angle. Set the length and stroke of the spring. Move the bottom mount point around. It'll give you all the information you need to know after that. The only vaguely hard part is entering how far away from the seam the lid end will mount.

The really hard part is figuring out where to place the spring so that it's strong enough to start lifting on its own at a useful point.

_________________________

Bitt Faulk

|

|

Top

|

|

|

|

#333267 - 24/05/2010 02:07

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

Re: Engineering/Mechanics lever questions/calculations.

[Re: wfaulk]

|

carpal tunnel

Registered: 12/11/2001

Posts: 7738

Loc: Toronto, CANADA

|

We're obviously on two completely different paths in thought here.

It's not the extension of the piston in between open and closed that I'm worried about. It's the extension when closed, which isn't necessarily fully compressed. When the lid is open, the spring will be at full extension unless I employ some other device to limit the lid opening. How compressed the spring is when closed depends totally on mounting position and that's what I don't see how to figure out without moving the lid.

The spring will actually only work in very few positions, irrespective of its force and the weight distribution of the lid. Speaking strictly of its ability to extend and compress, only very few positions for each end will allow the lid to get to the angle desired when open and flat when closed. Obviously the force is important to complete the functionality, but it's irrelevant if the lid can't be actuated through its desired path (from 0 to 65 in my case).

The idea behind me getting a compressible object into Sketchup was so that I could actuate the lid and check whether certain mounting locations would allow it to both close flat and open to the desired angle. That's why I mentioned being able to move the point which represents the most outward on the lid in ggb.

|

|

Top

|

|

|

|

|

|